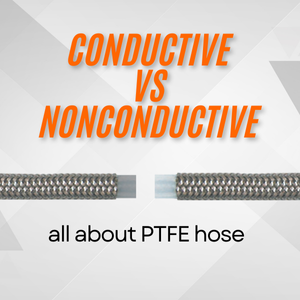

Conductive vs Nonconductive PTFE Hose in Automotive Use

Polytetrafluoroethylene (PTFE) hoses are widely used in the automotive industry due to their unique properties such as high pressure and temperature resistance, chemical inertness, and low friction. These hoses are used for various applications including fuel lines, brake lines, vacuum lines, and coolant hoses. However, PTFE hoses can be broadly categorized into two types: conductive and nonconductive. The main difference between these two types of hoses is their electrical conductivity, which plays a crucial role in their application and performance. Below we’ll discuss the difference between conductive and nonconductive PTFE hoses in automotive use.

Nonconductive PTFE Hoses

Nonconductive PTFE hoses do NOT have a conductive liner. This means that they do not conduct (dissipate) electricity and cannot be used in applications that require grounding. The lack of conductive materials in nonconductive PTFE hoses makes them more resistant to certain chemicals and solvents that can attack the compounds in conductive PTFE hoses. This makes them suitable for use in applications that require exposure to aggressive chemicals or solvents. Nonconductive PTFE hoses also have a lower coefficient of friction compared to conductive PTFE hoses, which makes them ideal for use in applications where high pressure and the reduction of friction is important. This includes applications such as brake, clutch, hydraulic, and vacuum lines.

However, one of the main disadvantages of nonconductive PTFE hoses is their inability to dissipate static charge. This means that they cannot be used in applications that require grounding, such as fuel lines. In this applications, the buildup of static charge can be dangerous and could result in an explosion if not properly dissipated.

Conductive PTFE Hoses

Conductive PTFE hoses are those that have a conductive resin liner, which allows them to conduct electricity. This type of hose is often used in applications that require grounding. The conductive lining provides a path for static electricity to dissipate from the hose, preventing the buildup of static charge. The buildup of static charge can be dangerous in certain applications where a spark could ignite the fuel and cause an explosion, which makes the conductive liner ideal for use in fuel lines running gas, E85, methanol and more.

The conductive liner in PTFE hoses is usually made of carbon black, which imparts conductivity to the PTFE material and gives it a distinct grey tint. The liner is embedded in the PTFE material during the manufacturing process, ensuring uniform conductivity throughout the length of the hose.

Conclusion

Conductive and nonconductive PTFE hoses are two types of hoses widely used in the automotive industry. The key difference between these two types of hoses is their electrical conductivity, which plays a crucial role in their application and performance. It’s for this reason that Phenix offers nonconductive hose in our -03 and -04 sizes, while -06, -08 and -10 now come standard in conductive PTFE with safety in mind. Both types of hoses have an outer stainless wire braiding providing additional reinforcement to the hose, making it more resistant to kinks, abrasion, and punctures. This makes PTFE hoses ideal for use in harsh environments, such as under the hood of a car, where they may be exposed to high temperatures, chemicals, and mechanical stress while far outlasting the lifespan of typical CPE inner hoses. Both types of hoses have their advantages and disadvantages, and it is important to choose the right type of hose for each application to ensure safe and effective performance.