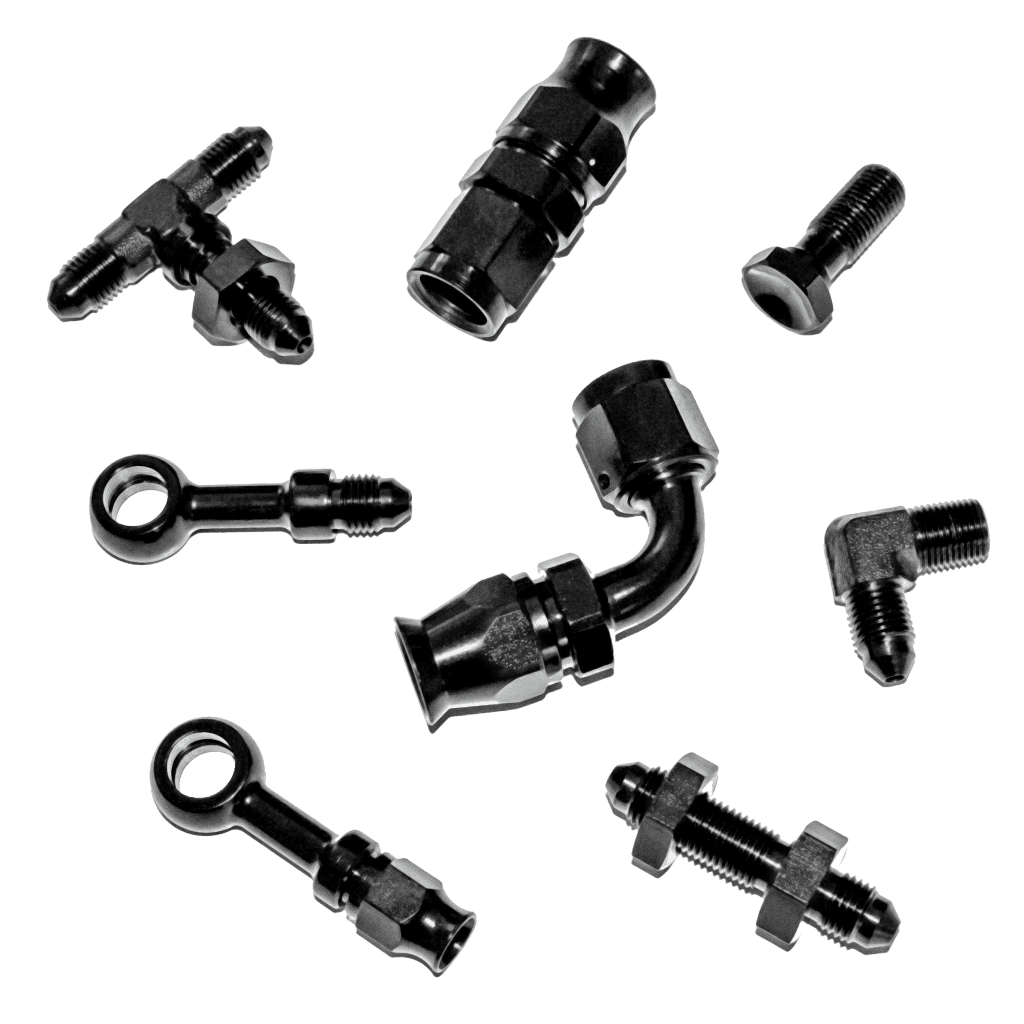

Metric Fittings

In the automotive industry, metric-sized fittings are commonly used for a variety of systems such as fuel lines, hydraulic brake systems, air conditioning, and engine components. These fittings, which adhere to the metric system, use measurements in millimeters (mm) rather than the imperial system (inches) commonly seen in North America. In vehicles manufactured in regions like Europe, Japan, and other parts of the world, metric fittings are standard, so understanding them is essential for anyone working on or maintaining these vehicles.

Key Features of Metric-Sized Automotive Fittings

- Thread Type and Pitch:

- Thread Diameter: The thread diameter is typically measured in millimeters. For example, an M10 fitting refers to a fitting designed for a pipe or component with a nominal outer diameter of 10 mm.

- Thread Pitch: The pitch refers to the distance between threads, measured in millimeters. For example, M10x1.5 means a 10 mm nominal diameter with a 1.5 mm thread pitch.

- Common Applications:

- Fuel Lines: Metric fittings are widely used for fuel line connections in modern vehicles, where durability and precise sealing are essential.

- Brake Lines: Hydraulic brake systems, especially in European cars, rely on metric-sized fittings for safe and efficient operation.

- Air Conditioning Systems: Automotive A/C systems often use metric fittings for connecting hoses and refrigerant lines.

- Engine and Transmission: Metric fittings are also found in various engine components such as oil coolers, water pumps, and transmission fluid lines.

- Suspension and Steering: Some suspension and steering systems use metric fittings to handle hydraulic pressure, such as power steering systems.

- Sealing Methods:

- Compression Fittings: Often used in automotive fuel and brake lines, these fittings use a ferrule or sleeve that compresses to create a seal.

- O-Rings and Seals: O-ring seals are widely used in automotive hydraulic systems, ensuring that fluid does not leak under pressure.

- Crimped Fittings: These are used for high-pressure systems like air conditioning or fuel lines to create a leak-tight connection.

Metric Fitting Sizes Used in Automotive Applications

Here’s a chart showing typical metric-sized fittings commonly used in the automotive industry. The nominal size (diameter) and thread pitch determine the fitting’s compatibility with specific components.

| Nominal Size (mm) | Thread Diameter (mm) | Thread Pitch (mm) | Common Automotive Use |

|---|---|---|---|

| M6 | 6 | 1.0 | Small fuel lines, A/C lines, bolts |

| M8 | 8 | 1.25 | Engine components, fuel injection, A/C |

| M10 | 10 | 1.5 | Brake lines, fuel lines, A/C systems |

| M12 | 12 | 1.75 | Power steering, oil cooler lines |

| M14 | 14 | 2.0 | Brake fluid reservoirs, hydraulic lines |

| M16 | 16 | 2.0 | Larger fuel or brake lines, turbo systems |

| M18 | 18 | 2.5 | High-pressure hydraulic connections |

| M20 | 20 | 2.5 | Transmission cooler lines, power steering |

| M22 | 22 | 2.5 | Heavy-duty brake lines, A/C compressor connections |

| M24 | 24 | 3.0 | Large hydraulic fittings, suspension systems |

| M30 | 30 | 3.5 | High-pressure fuel or oil lines |

Important Considerations for Automotive Metric Fittings

- Thread Pitch and Compatibility: When working with metric fittings in automotive systems, it’s crucial to ensure that the thread pitch matches exactly. Even slight differences in pitch can cause leaks or difficulty in achieving a secure connection. For instance, an M10x1.25 fitting will not work properly with an M10x1.5 fitting, even though the nominal size is the same.

- Material Selection: Metric automotive fittings come in a variety of materials, depending on their application:

- Brass: Often used in low-pressure fuel and coolant lines due to its corrosion resistance.

- Steel/Stainless Steel: Typically used for brake lines, high-pressure systems, and fittings that require higher strength and durability.

- Aluminum: Sometimes used in engine components and air conditioning systems due to its light weight.

- Sealing and Leak Prevention: Automotive systems, especially those dealing with fluids like brake fluid, oil, fuel, or refrigerant, require fittings that ensure a leak-free seal. This is often achieved using compression seals, O-rings, or even thread sealants designed for high-pressure systems.

- Torque Specifications: Proper tightening of metric fittings is critical in automotive applications. Over-tightening can lead to thread damage, while under-tightening may result in leaks. Always follow manufacturer torque specifications.

- System Pressure and Vibration: In automotive systems, components often experience high pressure (like in brake lines) or constant vibration (as in fuel lines or power steering). Metric fittings are designed to handle these stresses, but the right sealing mechanisms must be used to maintain performance.

Understanding metric-sized fittings is essential for anyone working on vehicles, particularly those from European or Japanese manufacturers. These fittings play a critical role in ensuring the proper operation of systems like fuel, brake, air conditioning, and hydraulic components. Always ensure you use the correct fitting size, material, and sealing methods to avoid leaks and ensure safe operation in automotive applications.